Taurus 4000

Taurus 4000

The Taurus 4000 is C&G Systems’ precision, large-format machine series. The Taurus line is designed for use with the latest in today’s Precision Plasma cutting systems as well as multi-head oxy-fuel applications. Taurus is available in standard widths from 8’ (1.5m) to 24’ (7.3m), and can be extended to over 150’ (45m) in length and comes with standard heat shields.

Plasma & Oxy-Fuel Cutting

This large format machine is capable of carrying up to ten cutting stations. Taurus can be equipped with up to 4 plasma stations with power to 1,000 amps. Up to 8 oxy-fuel stations with automatic ignition can be installed for maximum productivity.

Heavy Duty Frame & Rail System

Rugged frame and rail system components are designed to perform in the most demanding environments. Large structural steel tubing is welded together to form the end trucks and cross axis beam. Mating assembly surfaces are precision machined and ground for maximum accuracy. Large diameter crowned and hardened truck wheels glide over precision machined, tongue-in-grooved sections of 115# T-Rails. Precision AGMA gear rack insures repeatability and accuracy throughout the entire cutting envelope.

Precision Controls

The Taurus line comes standard with a PC-based Hypertherm EDGE® Connect controller. Dual-stage planetary gear-heads mounted directly to 3500 Watt AC servo motors provide exacting motion control and ultra smooth cut surfaces. Digital interfaced amplifiers insure accurate control of machine motion from 1-750 IPM.

Torch Height Control

Taurus is equipped with the Sensor® THC plasma torch height control system. Pierce height is precisely set each time the arc starts. The high-resolution (+/-4V) arc voltage regulator controls and constantly maintains the torch-to-work distance during cutting to optimize the quality and finish of your plasma cut parts. Arc voltage set point, pierce height, cut height and retract distance are all displayed on the EDGE® Connect touch screen.

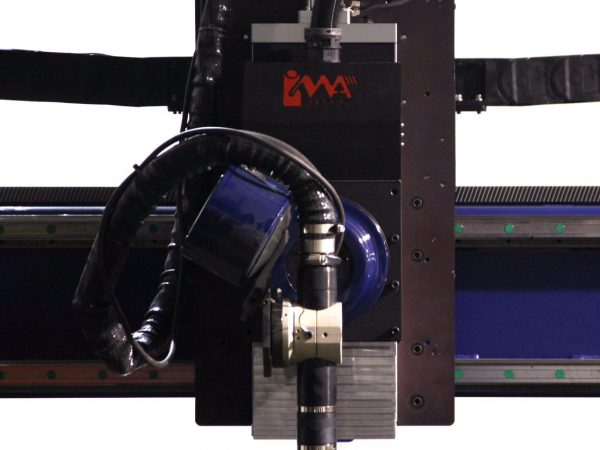

Precision Plasma

The Taurus 4000 comes standard with the Hypertherm XPR 300™ X-Definition plasma system or optional HyPerformance® HPR 400XD or 800XD plasma. An

A-B Tilt Plasma Bevel Station is optional.

Options

C&G Systems offers a full line of options to configure and customize your Taurus with. Options include: motorized oxy-fuel stations with automatic ignition, zoned down draft or water cutting tables, exhaust systems, dedicated compressor systems, professional CAD/CAM, and nesting software packages.

System Specifications

- Standard Cutting Widths From 8’ – 24’ (2.4m – 7.3m)

- Custom Widths Available Upon Request

- Cutting Lengths:

- Standard Length Is 13’ (4m), With Extensions Up To 150’

- Constructed Of Heavy Structural Steel Tubing

- Cutting Station Capacity

- 10 Stations Maximum

- Up To 4 Plasma Stations

- Up To 8 Oxy-Fuel Stations

- Precision Plasma Systems Up To 800 Amps Available

- PC-Based Hypertherm EDGE™ Connect Controller

- Easy-To-Use 19″ Touch Screen Operation

- Windows 10 Operating System

- Solid State Hard Drive

- USB Ports, Wireless Connectivity

- 750 IPM Drive Package

- 3500 Watt, Brush-less AC Drive Motors

- Precision Linear Ways

- Floor Mounted Rail Systems

- 115#, Tongue-In-Groove T-Rails

- Cable Drive Torch Positioning

- Enclosed Power-Track On All Axis

Optional Equipment

- Standard XPR 300 Precision Plasma, Optional HPR 400XD, HPR 800XD

- Plasma Bevel Head

- Oxy-Fuel Stations

- Air Exhaust Or Water Cutting Tables

- Exhaust Systems

- Dedicated Air Compressors & Dryers

- Clean Air Package

- Professional CAD/CAM And Nesting Software Packages

Contact Us

Download and Print Brochures

Contact Us

C&G Systems

320 East Main Street

Lake Zurich, IL 60047

Phone: (847) 816-9700

Fax: (847) 816-9777

Let us create your sample!